⌖ Via Fiume Tavo 51/3 • 65010 Cappelle sul Tavo (PE)

☎ +39 085 447 1291

✉ flaviano.liberatore@pfmautomazioni.it

Tax Code and VAT No.: 01871690689

ELECTRICAL PANELS

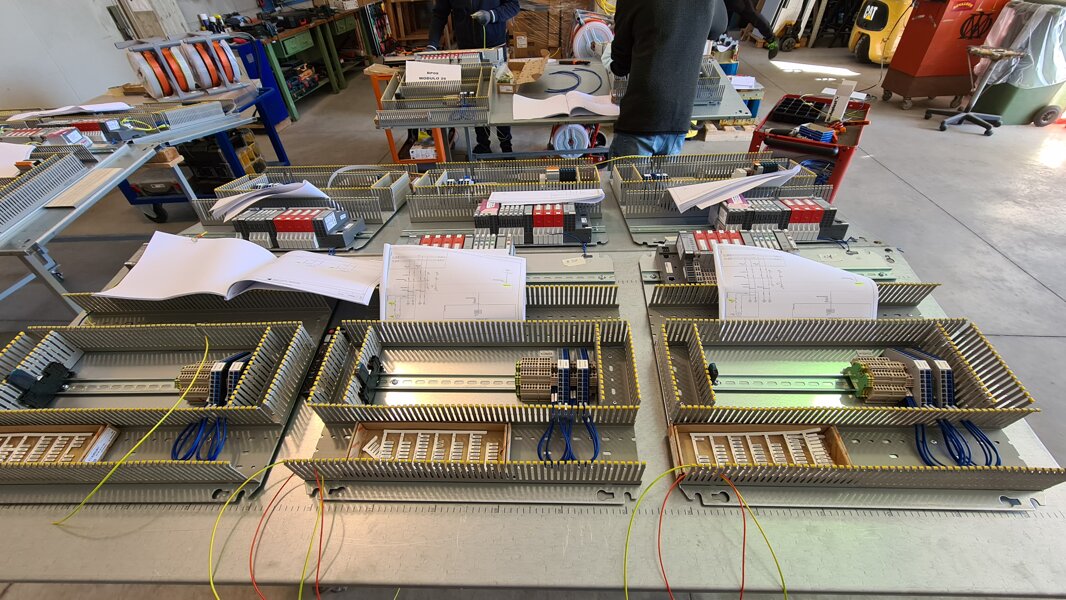

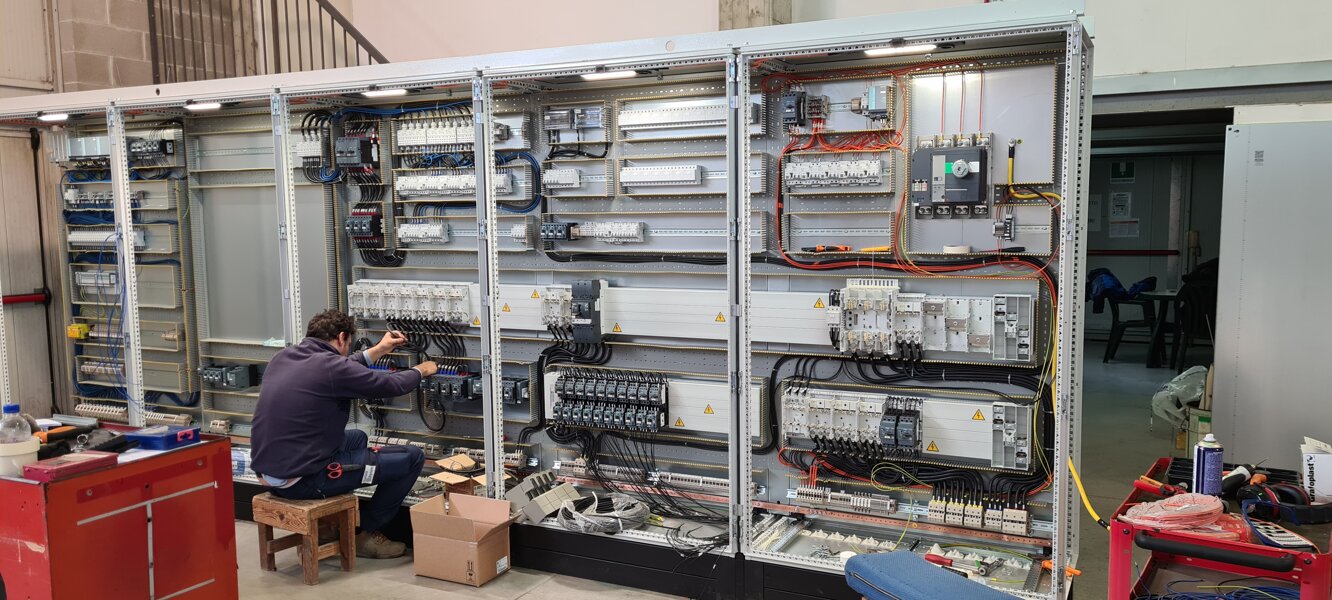

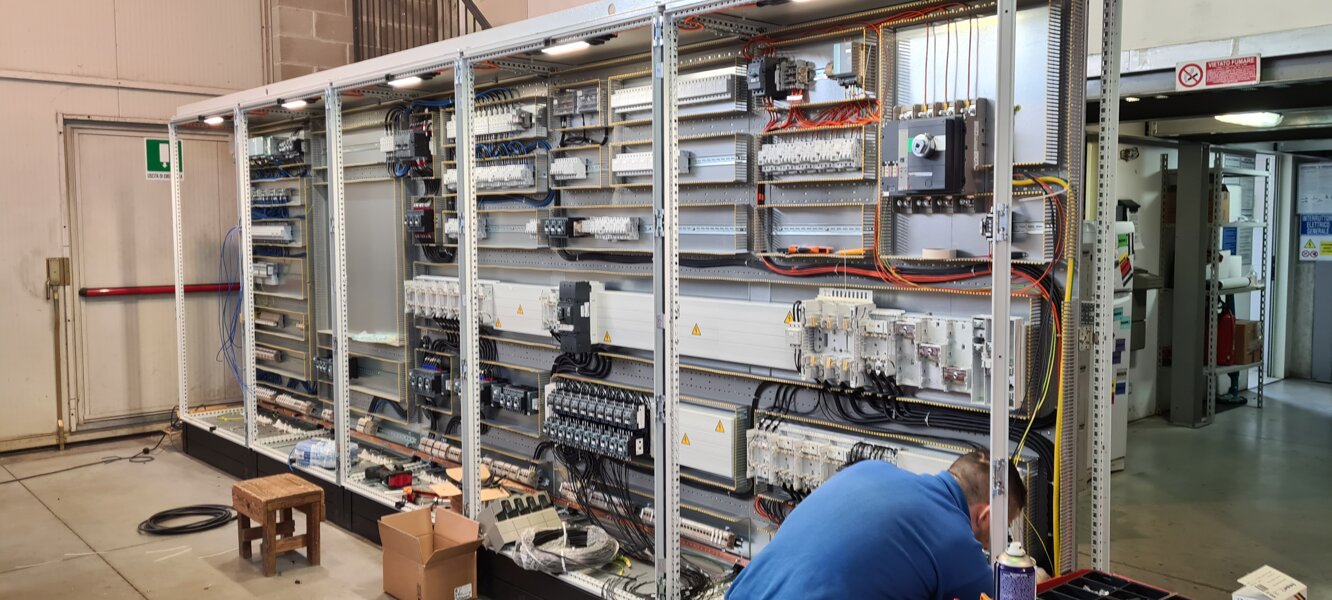

In PFM AUTOMAZIONI the processing of ELECTRICAL PANELS begins with the storage of materials, which are carefully picked, labeled, and divided into batches according to the design of each individual panel. This first step allows for a significant reduction in the time needed by the technicians in charge of wiring to search for materials.

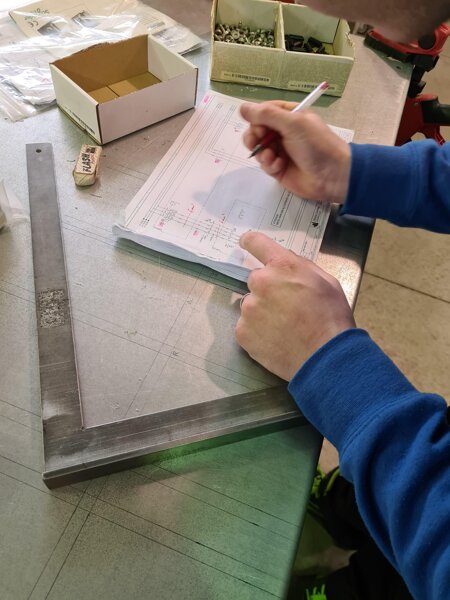

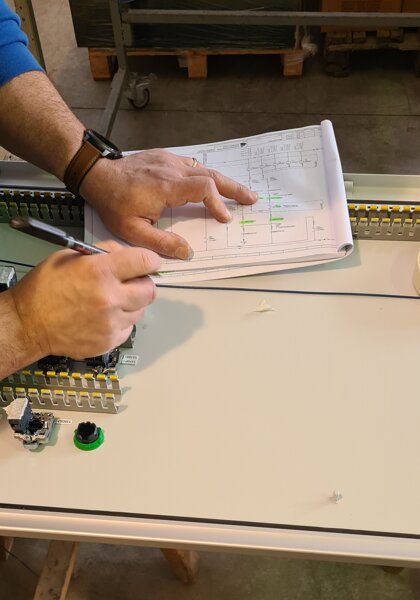

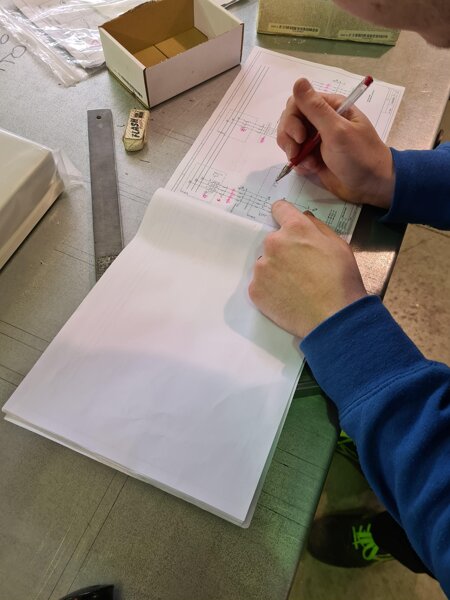

Following the electrical diagrams previously designed, the guidelines to be followed during wiring are then reproduced on the panel of the board.

After this initial preparation, work begins on the internal plates of the cabinets with drilling, tapping and installation of cable ducts, the framework for the cable routes, where the cords intended for wiring the power and auxiliary circuits will be laid.

The internal plate is completed with the positioning and identification of the individual devices as specified in the electrical diagrams.

At this point it is possible to proceed with the wiring of the electrical panel.

Then proceed with the closure of the cable ducts and the general closure of the panel.

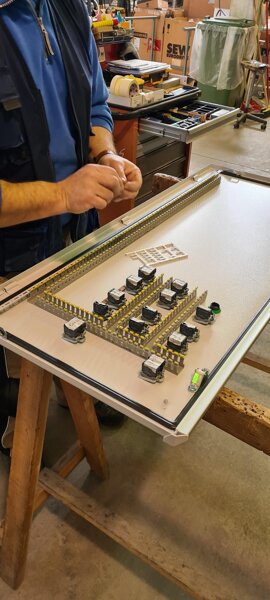

In parallel with the electronic work, a dedicated section is reserved for the mechanical processing of the electrical panels: the frameworks are assembled into cabinet banks, intended for the operator control, and then drilled for the insertion of buttons, selectors and indicator lights.

The final step is dedicated to the final inspection of the panel, so that its correct operation can be verified.

⌖ Via Fiume Tavo 51/3 • 65010 Cappelle sul Tavo (PE)

☎ +39 085 447 1291

✉ flaviano.liberatore@pfmautomazioni.it

C.F. and VAT: 01871690689